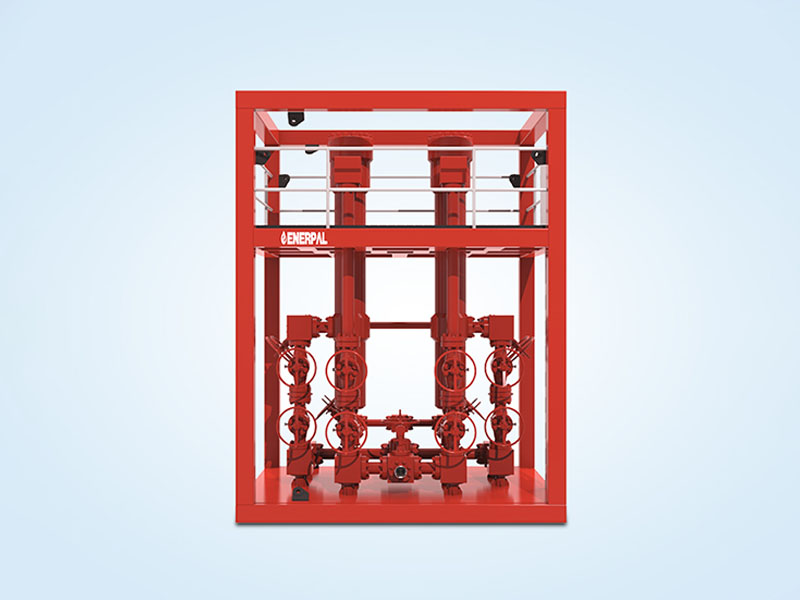

Dual Pot Sand Filter

Dual Pot Sand Filters are available in two basic configurations (Type A & B) and a broad range of sizes and configurations, up to 20,000psi WP.Dual Pot Sand Filter is designed for the mixed gas, oil and water flow.

Applications

- Wellstream Sand removal

- Well Test Cleanup

- Coiled Tubing Cleanup

- Underbalanced Drilling Operations

|

| Dual Pot Sand Filter |

Product Description

Dual-pot sand filters are primarily used in the oil and gas industry to remove sand and other solid particles from well fluids during well testing and production. They are crucial for preventing erosion of downstream equipment like choke valves and other processing equipment. These filters feature two filtration vessels, allowing continuous operation while one vessel is cleaned.

A dual pot sand filter by Enerpal is a screen based process system that provides a cost effective solution for the separation and removal of solids from multi-phase fluids. Enerpal Dual Pot Sand Filters are pressure drop independent, where solids laden multi-phase fluids pass through a screen causing the solids and fluids to separate. The solids accumulate and are stored in the hold up section of the filter vessel and when full, is isolated,and bypassed for solids removal. The solids are then flushed from the system by a series of valves and pipework. Once all the solids are purged,the filter vessel is brought back into production.

How it Works: A dual-pot sand filter typically consists of two filter vessels connected to a manifold. One vessel is online, filtering the wellhead fluid, while the other is offline, either being cleaned or ready to be switched into service. A sand jetting system or other method is used to clean the offline vessel and remove the accumulated sand. The flow is then switched to the cleaned vessel, allowing for continuous operation.

Benefits

- No moving parts, low maintenance and reduced downtime result in significant capital and operating cost savings;

- Activates oil and gas wells previously shut-in due to excessive sand production;

- Eliminates solids erosion on downstream pipework, valves, chokes, and process vessels;

- Provides solids removal prior to oil contamination and eliminates sludge formation and other difficult solids accumulation problems.

Operations

- Pot Filters are available in many sizes; typically separating particles in the 200 microns range and larger;

- Operating pressure drop requirements vary from 10 to 60 psi,with the larger units handling solids volumes of up to 30%.

Product Specification

- Pressure Ranges: 5,000 psi ,10,000 psi ,15,000 psi

- Material Classes: AA,BB,CC,DD,EE

- Temperature Rating: K to U (-60°C to 121°C)

- Gas flow capacity: up to 3,000,000 m3/d

- Pot volume: 46 L

- Liquid flow capacity: up to 15,000bpd

Contact Us

Sales Manager: Kinson

Email: kinson@enerpaltech.com

Tel: +86 178 0259 9535

WhatsApp: +86 178 0259 9535

Technical Manager: Leo

Email: leo@enerpaltech.com

Tel: +86 134 0174 3108

WhatsApp: +86 134 0174 3108

Quality Manager: Bill

Email: bill@enerpaltech.com

Tel: +86 134 0174 3108

WhatsApp: +86 198 5098 9788